Greywater recycling

In my last insider’s column I wrote that, at its core, harvesting rainwater is beautifully simple. I would say that the exact opposite applies to recycling greywater for use back in a building1. Waste water from baths, showers and wash basins has a high organic load which starts to deteriorate after 24 hours. There are different methods of treating greywater – biological, chemical, mechanical, or a mixture. All work, but the withdrawal of two of the main system suppliers from the UK market in the last 18 months, (the Ecoplay and the smaller Pontos Aquacycle units) shows the difficulty of providing small greywater recycling systems at a commercial price that meet customer requirements. Systems that use membrane filtration combined with biological action are still available on the UK market, but are only really cost-effective in commercial situations.

Wastewater heat recovery

So, is there a better option than recycling greywater? What about recovering the heat from the greywater as it runs to drain, or wastewater heat recovery (WWHR) as it is termed? In many non-domestic buildings, e.g. hotels, leisure centres, laundrettes, hospitals there is a large amount of heat lost to the drains from wastewater exiting the building, whilst heating hot water in dwellings produces 6% of the UK’s total CO2emissions, and reducing this figure is crucial. Heat is recovered from greywater by the simple science of heat transfer, with no power input required and no moving parts to maintain. The difficulty has always been capturing the heat effectively. Wastewater is usually run in horizontal plastic pipes, before mixing with foul water in a stack and running to drain.

Heat recovery from showers

In a commercial situation the wastewater can be routed separately to a plant room, run across a heat exchanger and the heat extracted put into a thermal store. But this is not possible in most dwellings, and so a solution is required that reuses the heat immediately. Welcome to the current generation of shower WWHR units. The beauty of a shower is that as the hot water runs to drain the requirement for new hot water continues. A thermostatic shower is fed from both hot and cold water. If the ‘cold’ water has been pre-warmed then less hot water is required to meet the design temperature. Hot water exiting a shower will run to drain at about 37oC. The WWHR units available can extract up to 17oC of heat from the wastewater and preheat the incoming mains water from 10 to 27oC. Best results are obtained when the unit is connected to a thermostatically controlled shower fed from a combination boiler, with the preheated mains supply feeding both the shower and the boiler.2However, the system will also work with an unvented cylinder or an electric shower.

How does it work?

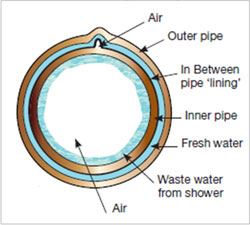

For efficient heat transfer metal pipework is required. First generation systems had thin copper pipe coiled around the outside of a metal section of waste pipe. New technology is far more effective. As water runs to drain down a vertical pipe it adheres to the side in a thin film. In vertical WWHR units, mains water rises up the outside of the unit in a twin walled copper pipe heat exchanger. The volume of the exchanger is less than one litre of water, so the effect of pre-warmed water is almost immediate. Not surprisingly, efficiencies are greater from lower flow rates as the film of hot water adhering to the sides of the pipe is thinner and so heat transfer occurs from more of the water running to drain. Validated testing show 62% of waste heat can be recovered from a shower with a flow rate of 7.5 litres/minute through a vertical WWHR unit. The units are 2m high so installation requires some thought and may not always be possible. There are horizontal heat exchange options available, supplied pre-fitted to a shower tray or in the drain from a wet room. Heat transfer is not as effective but efficiencies can still reach 45% at low flow rates.

For efficient heat transfer metal pipework is required. First generation systems had thin copper pipe coiled around the outside of a metal section of waste pipe. New technology is far more effective. As water runs to drain down a vertical pipe it adheres to the side in a thin film. In vertical WWHR units, mains water rises up the outside of the unit in a twin walled copper pipe heat exchanger. The volume of the exchanger is less than one litre of water, so the effect of pre-warmed water is almost immediate. Not surprisingly, efficiencies are greater from lower flow rates as the film of hot water adhering to the sides of the pipe is thinner and so heat transfer occurs from more of the water running to drain. Validated testing show 62% of waste heat can be recovered from a shower with a flow rate of 7.5 litres/minute through a vertical WWHR unit. The units are 2m high so installation requires some thought and may not always be possible. There are horizontal heat exchange options available, supplied pre-fitted to a shower tray or in the drain from a wet room. Heat transfer is not as effective but efficiencies can still reach 45% at low flow rates.

How much energy could a system save?

Obviously the longer the shower is used the more heat is available to be recovered. A family of four, with a shower flow rate of 7.5 litres/minute, each taking a five minute shower a day, would need 55m3 of hot water a year. To heat 1m3 of incoming mains water through 30oC (to provide 40oC at the shower head) requires 35kWh of energy, so 1,925 kWh in total. It is unlikely that savings in a real life situation will be as great as from a test rig, but if the WWHR unit worked at 50% efficiency, 963 kWh of energy would be saved.

As with most sustainable building solutions, a competitive cost, Government support or legislative requirements, ease of installation and minimal maintenance requirements determine how successful any new product will become. Currently these units are expensive but with support from SAP (as an Appendix Q technology3) and as a nominated Green Deal measure, an increasing market will drive costs down. It is certainly a technology that architects, designers and specifiers should be considering.

Notes

- Direct use of greywater in the garden is another matter entirely. I have been doing that for the last ten years and cannot recommend it highly enough.

- These WWHR units are imported from the Netherlands. The combination boiler must be able to accept pre-heated hot water. Many in the UK do not.

- Not if connected to an electric shower. An electric shower works ‘better’ in that it can provide hot water at a higher flow rate as the temperature of the incoming cold water is now greater, but will not reduce the amount of energy it uses.