On a recent geological trip to the Harz Mountains in Northern Germany, Margret and Rolf found this perfect swimming spot (below) near where they were staying. To their surprise they had stumbled upon a water management system that is so unique it was declared a UNESCO World Heritage Site in August 2010. Mining in the Harz started in the Middle Ages and stopped in 1988 after over 1000 years of almost uninterrupted mining.

The Upper Harz Water Management System was created to serve the mining activities and is today regarded as the world’s most important pre-industrial energy supply system. It consists of a unique and complex system of water storage ponds (for energy storage) and transport ditches on the surface, underground tunnels and water wheels. It was created from the 16th to the 19th centuries and provided water power for hoisting ore to the surface, for water pumps and later for transporting miners deep underground.

Today, there are 107 lakes, 310km of water ditches and 30km of underground waterways preserved; while 65 ponds, 70km of ditches and 20km of underground waterways are still in operation, used for energy supply, as flood protection, as drinking water storage or for recreational bathing.

Margret and Rolf by chance had stayed at one of the 65 ponds still in operation and had found (in Margret’s words) “the technical wonder, how they lead the water from one pond to the next to the mines.”

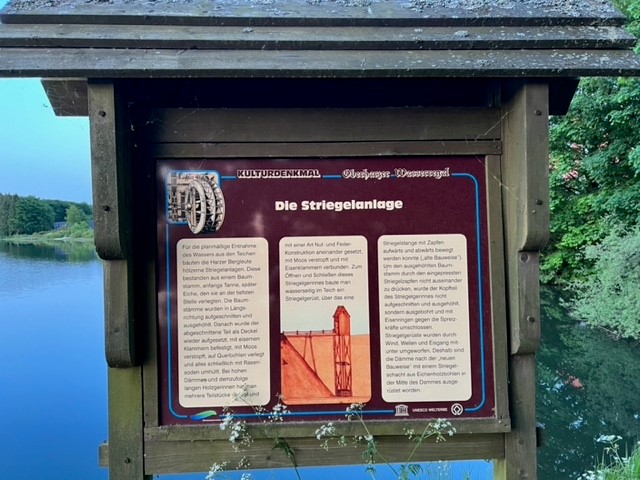

The little hut (in photo above) has a vertical big log (you can see it underneath) that closes a hole in a hollow oak trunk that crosses the dam to the next pond. So somebody had to handle this technical device (at the panel (below) it is called, ”Striegelanlage”), when the water was needed further down.

Okay, so far so good. But what to do, when they needed water the other way round? We got to know, that this is the miracle of the WIDERWAAGE. So we walked there to understand, how they managed this problem. And the information panel told us something in German, which deepl tries to translate:

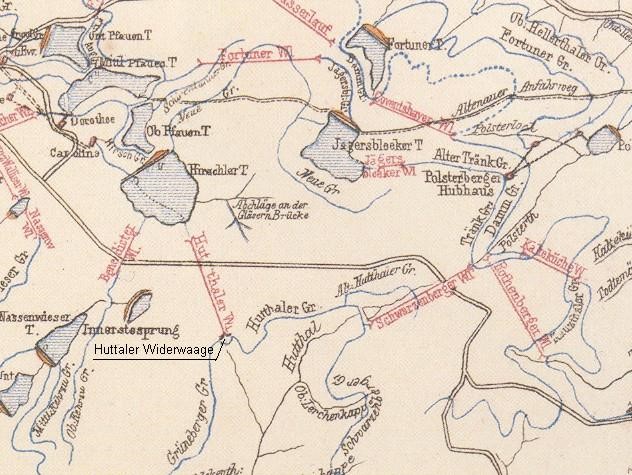

The Huttaler Widerwaage is a water counterbalance pond, constructed with natural stone walls and an arched stone bridge. It was built in 1763 to ensure a safe inlet and outlet to and from the Hirschler Pond through the 780 m long Hutthaler Watercourse. It serves the important principle of keeping the water as high as possible and enables the water in the attached Huttaler Graben (graben = ditch) and the Huttaler Wasserlauf tunnel to flow in both directions.

Here you can see the outlet hole and the pond with very little water. When the Hirschler Pond is full, it backs up into this counterbalance pond. From the right, the horizontal Hutthaler Graben flows in, which initially connected to the Upper Hutthaler Pond and is still connected to the graben in its pond dam today.

Don’t puzzle around, we ourselves only understood it a little and there is more information here on the UNESCO World Heritage Site and on Wikipedia.

Perhaps we are all a bit cleverer by now. The old water management definitely was. Hopefully it was as interesting for you as it was for us.

Supplementary information

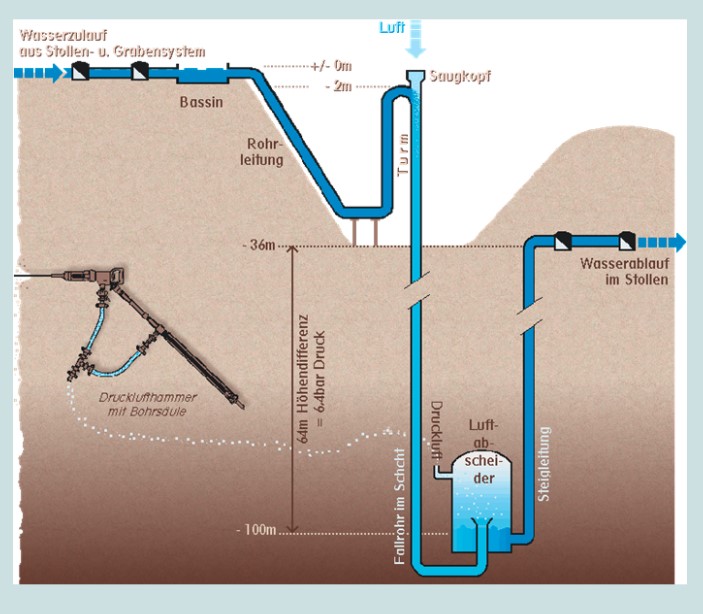

There are a whole series of walks around the area which is very extensive and parts of the system that Margret and Rolf didn’t see include the underground tunnels that are still accessible. There is the Oderteich, which was Germany’s largest and highest reservoir for almost 170 years, and still supplies water via the Rehberger Graben for the generation of electricity. In the Polsterberger Hubhaus pumps, driven by water wheels, lifted the water 18 metres into the Hirschler and Jägersbleeker storage ponds. Some of the water wheel were bi-directional, which moved in both directions depending on water levels and water flow direction. There was also a hydro compressor tower, which produced compressed air. Its method of working is explained below.

The hydro compressor works on the principle of a closed pipe. The production of compressed air takes place through water pressure (hydraulic). The water pressure is used directly, without any further power transfer, to compress the air. A hydro compressor consists of a water-filled downpipe, a riser pipe and a pressure tank functioning as the air separator at the deepest point of the pipe system. The downpipe is equipped with an open suction head for the intake of air. The falling of the water creates a lower pressure in the pipe, causing air to be sucked in and dragged down with the water. The permanent downward flow of the air/water mixture prevents the air from rising in the downpipe. The deepest point of the system contains the air separator. Here, the air separates again from the water but cannot escape and is therefore immediately available as compressed air. The height difference between the suction head and the outlet of the riser pipe dictates the usable water gradient. The pressure of the compressed air is determined by the height of the column of water in the riser pipe.